Take Control of Knee Pain

With D’s Knees!

Is kneeling pain slowing you down or making your job difficult? D’s Knees provide unmatched knee protection and comfort. They are like armor for your knees, providing protection far beyond what an ordinary knee pad can provide. They are designed to hold up to harsh conditions without weighing you down or getting in your way. Not only do they protect your knees, but they give your knees an opportunity to heal and recover while you continue to kneel!

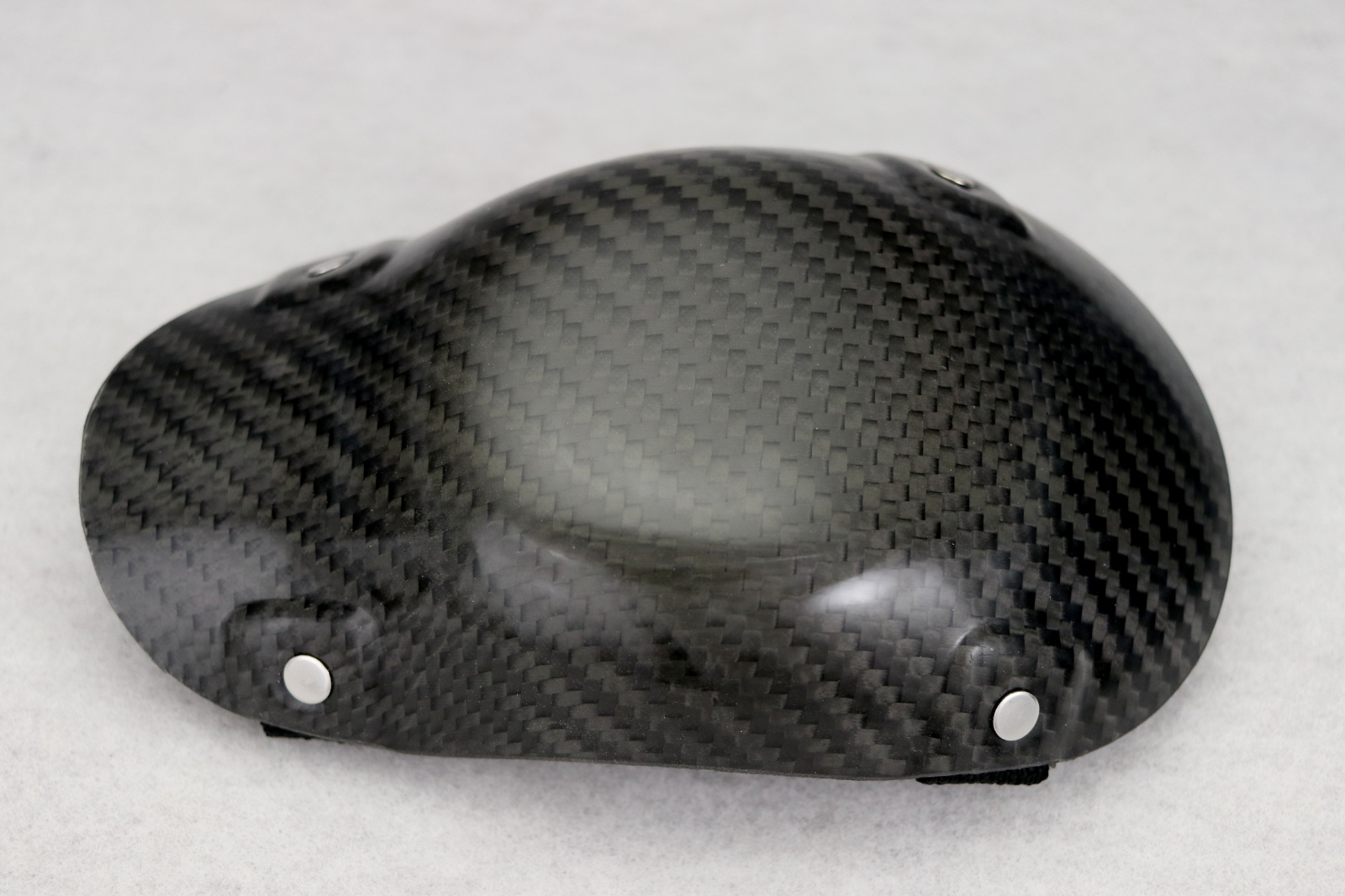

D’s Knees are a new, patented design. I call them “Knee Caps”. They work very differently from conventional knee pads. They are all about the rigid carbon fiber cap. This cap acts like a bridge that spans over the sensitive parts of your knee!

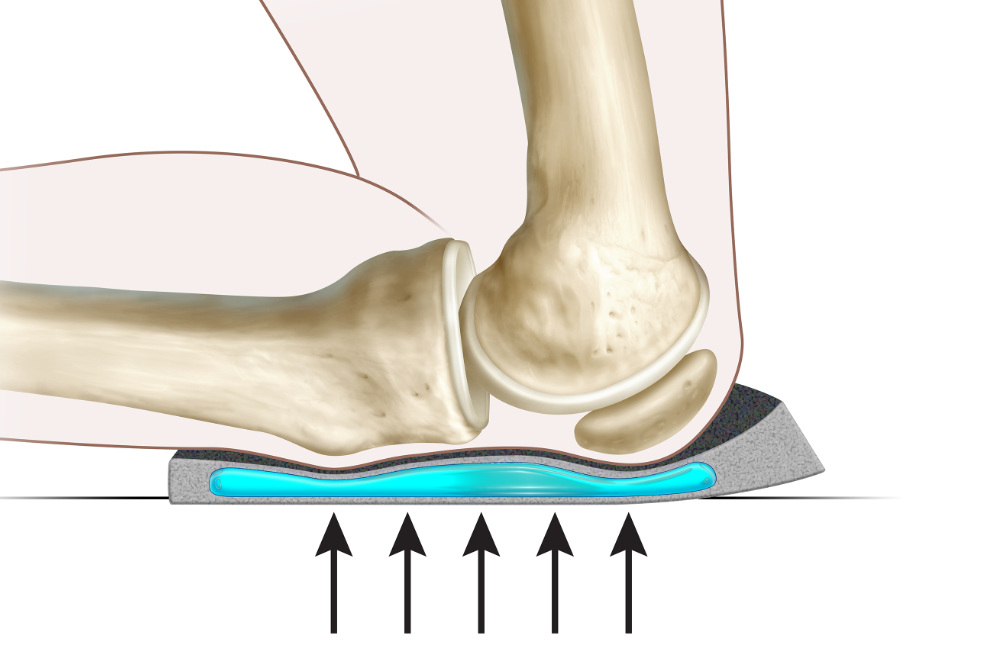

D’s Knees allow you to kneel comfortably, even with sore knees! Your knee can rest and recover while you continue to kneel every day! This is possible because the carbon fiber cap supports your knee while creating an air gap between your knee and the cap. Because of this gap, there is absolutely no pressure applied to the front of your knee! No pressure means no kneeling pain!

D’s Knees are available in 3 different sizes. “One size fits all” never fits everyone, and my goal is to provide a solution that genuinely works for everyone!

Whether you are starting a new career, you need to extend your career, or if you just want to do things you enjoy without kneeling pain, I believe D’s Knees will solve your kneeling pain!

Features:

- The Cap is made from REAL carbon fiber for light weight and strength

- Tough Urethane Rubber coating for traction and durability

- High Quality Laminated Foam pad with 3 types of foam

- Bamboo Face Fabric is wicking and durable

- Waterproof Cap keeps knees dry

- Self-Ventilated design prevents sweaty knees

- Made with genuine YKK buckles

- Hand Made in USA!

Try D’s Knees today and make kneeling pain a distant memory!

Let’s Talk About Knee Pads

There is a dirty secret in the world of knee pads. There are many knee pad designs, but nobody explains how their designs work and how they protect your knees. So if your current knee pads aren’t working, there is no way for you to know which design will work better or what design is the best.

I think you deserve better. You deserve to know why conventional knee pads always fail, and why the D’s Knees design is better than those designs!

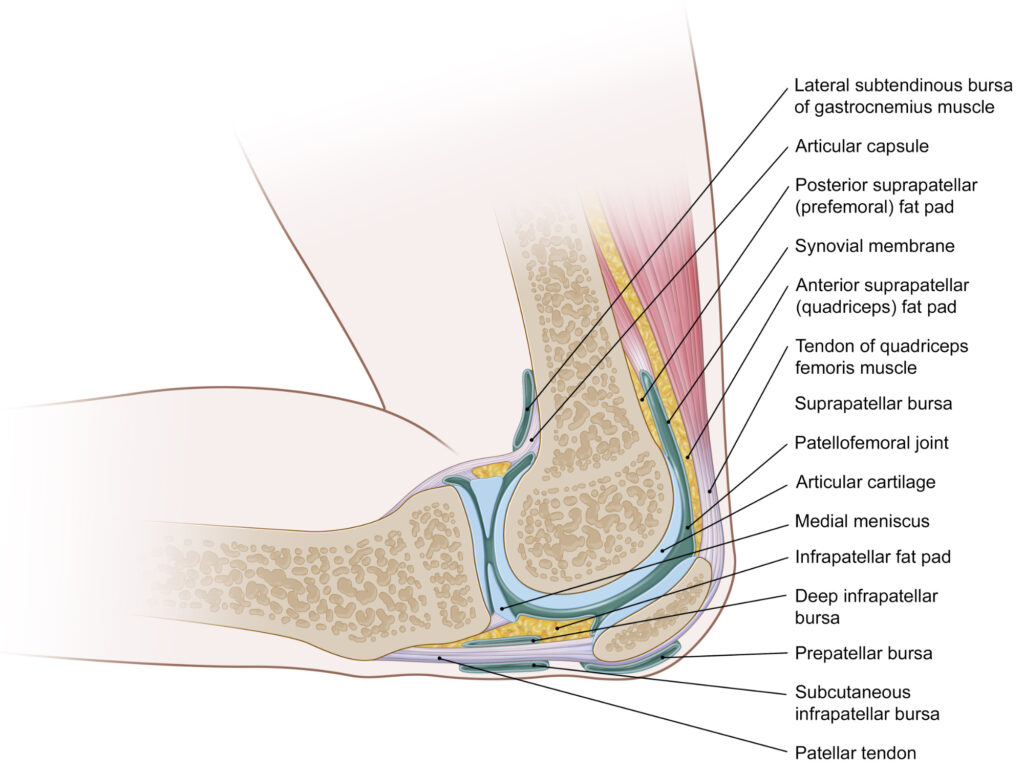

To explain the difference between D’s Knees and conventional knee pads, we need to start with the knee itself. The knee is more complicated than we realize.

Repetitive kneeling leads to discomfort and pain. The internal structures of the knee are not meant to be compressed by kneeling. Over time the pressure from kneeling can cause injuries to the knee, it can aggravate existing knee injuries, or the knee can simply become sensitive to kneeling pressure.

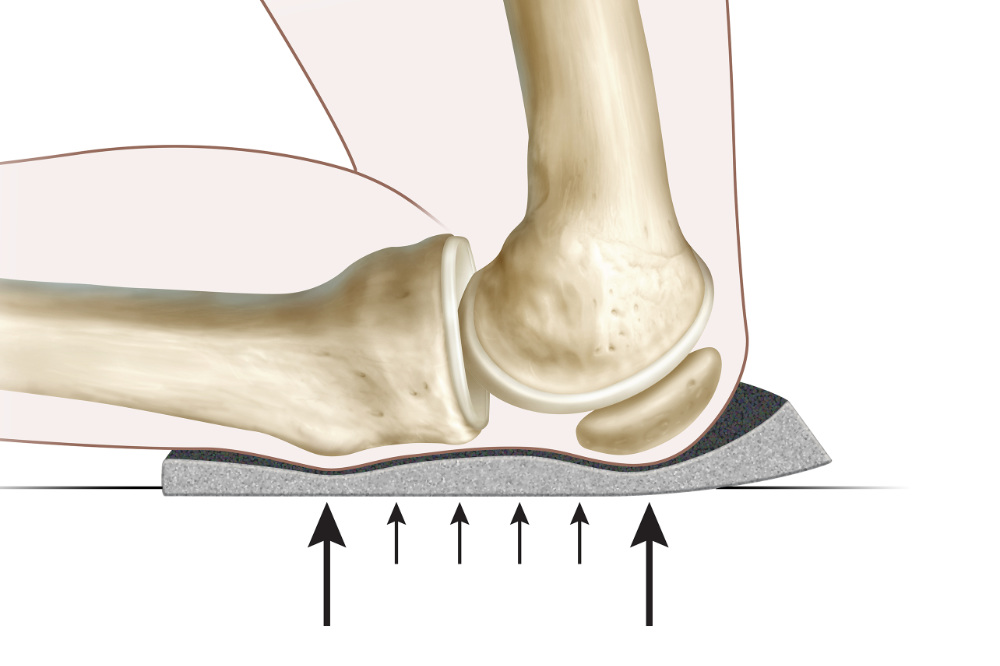

Knee pad designs all try to look unique, but conventional Knee Pads are just a foam pad. Once we realize this, the only thing left is to understand how foam works and why it has a limited ability to protect our knees.

Foam works by increasing surface area on our knee. We think of foam as being soft, but our knees only care about pressure! When kneeling, pressure is concentrated on a small area of our knee, which can be painful. To reduce this pressure, we need to spread out out over a larger area. Foam is the easiest way to spread out this pressure.

Many knee pads use foam that is too thin and too soft. Everyone prefers a knee pad that is compact, light weight, and inexpensive. So knee pad designs are made with thin and soft foam, which is thin, light weight and inexpensive.

To test foam on a knee pad, squeeze it with your fingers. If you can easily compress the foam with your fingers, it is too soft! It will not support you when you kneel on it.

Kneeling pads or knee pads with thick foam are better than thin foam. But the foam needs to be thick and firm! If the thick foam pad is thick enough and firm enouth, it will support your weight without fully compressing. When this happens, the foam is effectively spreading out pressure. But is this good for your knees?

My worst knee pad experience was with gel knee pads. I originally believed spreading out pressure was good, and I tried a gel pad because gel will spread out pressure better, putting equal pressure everywhere. I expected it to be better than foam, so I was surprised when just putting the gel knee pad on my knee caused significant discomfort! The gel put extra pressure on the sore part of my knee, which was very uncomfortable!

The gel knee pad taught me that the idea of indiscriminately spreading out pressure across a knee that is already sore doesn’t help the knee or solve the problem of kneeling pain. I realized I needed to find a better solution. I realized I need to transfer pressure to parts of my knee that are not sore or sensitive!

My solution is redistributing pressure. To do this, I created a carbon fiber cap that bridges over the front of the knee! This cap protects the soft tissues of the knee, and transfers the pressure to the bones of the knee and leg. Our bones are meant to supporting our weight, so this is a healthy solution. The cap also increases surface area, so it reduces pressure and redistributes pressure!

The D’s Knees Knee Cap is a patented design. It is a new idea about knee protection, and it is a huge improvement over conventional knee pad designs. It’s US Patent D981051.

OK, but aren’t hard shell knee pads kind of the same thing? Knee pads advertised as having a “hard shell” have a plastic outer layer instead of rubber. This hard plastic is usually still quite flexible and only meant to be slippery so you can slide your knees more easily. These “‘hard shell” knee pads are not designed to redistribute pressure like D’s knees!

D’s Knees are extremelly strong and durable. We already know that carbon fiber is strong and light, which makes it an ideal material for light weight knee pads. And in addition to the carbon fiber, I add a thick urethane rubber coating on top of the carbon fiber. The urethane is similar to roller blade wheels! It is the toughest material I can get my hands on, and it will provide secure traction and hold up to years of heavy use without wearing through.

D’s Knees have a high quality laminated foam pad. The carbon fiber shell protects your knee without needing foam, so the foam pad is just to enhance comfort. The pad is made from 3 different types of foam and a bamboo face fabric. The foam layers range from soft to firm. The soft foam conforms to your knee, and the firm foam absorbs impact. The bamboo face fabric is moisture wicking and adds durability.

D’s Knees are available in 3 different sizes. Humans are not all the same size, so why are knee pads always made in only one size? I believe that a good fit is an important feature for any piece of protective equipment!

D’s Knees Knee Caps are designed to be functional. Your weight is balanced directly above the natural balance point of your knee, so you can move and pivot on your knee naturally. They are very stable side to side, so they do not feel tippy. They form a secure work platform, allowing you to do whatever you do with confidence!

Do D’s Knees stay in place on your knees? Yes. If adjusted correctly, D’s Knees will stay on your knees all day long! Are the straps too tight? Buddy, those straps didn’t tighten themselves! The solution is simple, so the failure of other designs just proves how cheaply they are made! I use genuine YKK buckles, which helps the straps hold their adjustment. The straps should be kept fairly loose, much looser than most people expect. Their fit and adjustment is a little different from conventional knee pads, so understanding how they are meant to fit is important to ensure you have the best experience with them.

Did I mention they are Hand Made in America? D’s Knees are unique because I make every one of them myself in my garage in Minnesota. I have done everything myself, so no part of the design was made overseas! I hand laminate the carbon fiber, I overmold the urethane rubber, I trim them, cut and form the foam, cut and sew the straps and assemble them myself. This process requires a variety of molds and tools, and I designed, machined, and hand finished all of the molds and tooling myself! I’ve spent years perfecting the design, testing them at my day job while I worked to develop the tooling required to produce them.